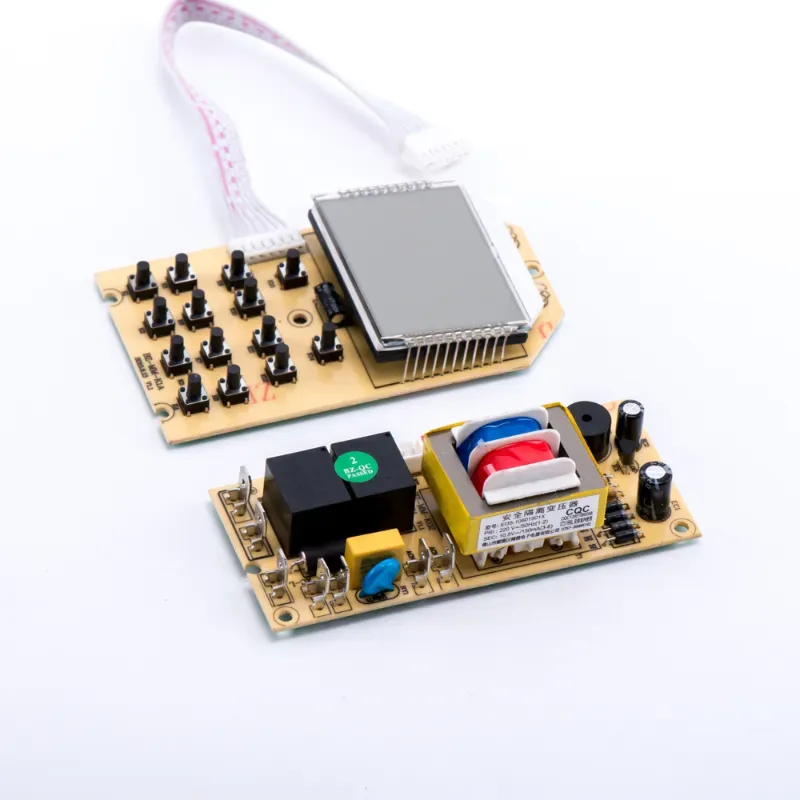

In the world of electronics manufacturing, the role of a PCB (Printed Circuit Board) assembly manufacturer is crucial. PCBs serve as the backbone of most electronic devices, and finding the right manufacturer can significantly impact the performance and reliability of your electronics. In this article, we'll explore the importance of selecting the right PCB assembly manufacturer and answer two frequently asked questions.

The Significance of a Reliable PCB Assembly Manufacturer:

1. Quality Assurance: A reputable PCB assembly manufacturer adheres to strict quality control standards throughout the production process. This ensures that your PCBs meet industry standards and are free from defects that could lead to malfunctions.

2. Expertise and Experience: Experienced manufacturers bring a wealth of knowledge to the table. They understand the complexities of PCB assembly, including component sourcing, soldering, and testing. Their expertise can lead to more reliable and efficient electronic products.

3. Customization: Different projects may require specific PCB designs or features. Established manufacturers can offer customized solutions tailored to your unique needs, from single-layer to multi-layer boards and from rigid to flexible PCBs.

4. Cost Efficiency: While quality is paramount, a reputable manufacturer can also help you optimize costs. They can assist in sourcing cost-effective components and offer economies of scale, making your project more budget-friendly.

Frequently Asked Questions (FAQs):

Q1: What is the lead time for PCB assembly manufacturing? A1: The lead time for PCB assembly can vary significantly depending on factors such as the complexity of the design, quantity, and the manufacturer's current workload. It's advisable to discuss lead times with your chosen manufacturer during the project planning phase.

Q2: Do PCB assembly manufacturers offer testing services? A2: Yes, most PCB assembly manufacturers offer testing services to ensure the quality and functionality of the assembled PCBs. Common testing methods include functional testing, in-circuit testing, and X-ray inspection to identify defects and ensure reliability.

In conclusion, selecting the right PCB assembly manufacturer is a critical decision for any electronics project. A reliable manufacturer can provide you with high-quality, customized PCBs that meet your specifications and industry standards. Whether you're designing consumer electronics, industrial machinery, or medical devices, partnering with an experienced and reputable PCB assembly manufacturer is a smart investment in the success and reliability of your electronic products. When in doubt, don't hesitate to reach out to manufacturers to discuss your project's specific requirements and ensure a smooth collaboration.

No comments:

Post a Comment